Boxford Cad Cam Software - fasrsavings. Boxford Manuals Instruction Manual and User Guide for Boxford. We have 7 Boxford manuals for free PDF download. See how the Boxford CADCAM Design Tools software creates 2D CAD files and processes them into 2.5D CNC machining programs utilising the seamlessly integrated CAD package. BobCAD-CAM 2017 V30 614.5 mb. 1990 25 hp mercury outboard repair manual. Information: Pioneer CNC Software Provider announces the release of their New Version 30 CAD-CAM software offering new features and enhancements. BobCAD-CAM, Inc. Develops CAD-CAM CNC machining software for manufacturing businesses and they have just announced the release of the new version 30 edition of their. The 5.0 version of Boxford CAD CAM Design Tools is available as a free download on our software library. This PC software can be installed on 32-bit versions of Windows XP/7. Epiphone serial number lookup. T splines v4 serial number product key. Our built-in antivirus checked this download and rated it as virus free.

Cad Cam Dental

Boxford V10 Cad Cam Crack Download

.png)

Cad/cam Technology

Massive thanks to Ian who helped move the mill (and its table and engine crane use to lift it!) from Crowthorne and then spend the rest of the night learning and tweaking the mill/software.

Lots of time spent on setting up (datums, vice offsets, tooling offsets etc) but it was worthwhile and the process to add extra tooling seems easy and solid.

We plan to spend time over the next couple of weeks fine tuning, fixing and documenting so others can then use the mill.

Wiki page created - http://rlab.org.uk/wiki/Boxford_260_VMC

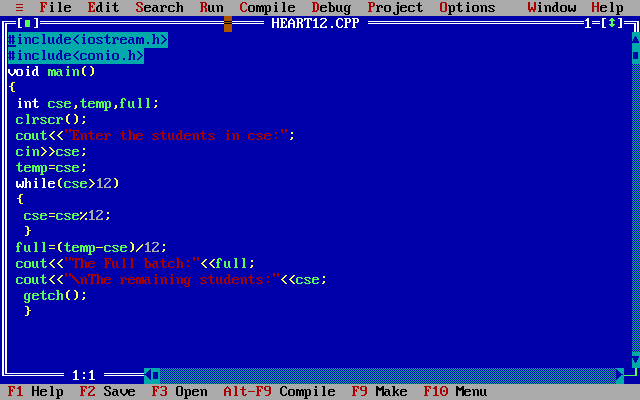

The CAD/CAM side of things is less solid..It uses a program called TechSoft Design which 'works' but is 2.5D only and has many 'quirks'. I would like the option of using Fusion 360 for this part so I am looking to see if any of the standard Fusion post processors will fit with Boxfords idea of gcode (should do as from what I have seen the boxford code looks normal).

Offers of help/advice are more than welcome!! Please chat to me of Ian rather than jumping straight in though as not everything is documented.

Top learning for the day..

Crashing a 40mm facing cutter in to plastic makes a louder and more painful noise than I would have expected.. :/ machine was fine but the plastic wasn't happy :D

WARNING!!!

If the mill is in your way please please please be very careful moving it. It is on wheels but is very top heavy so a minimum of 2 people and going very slowly is essential for safety!

Cheers,

James